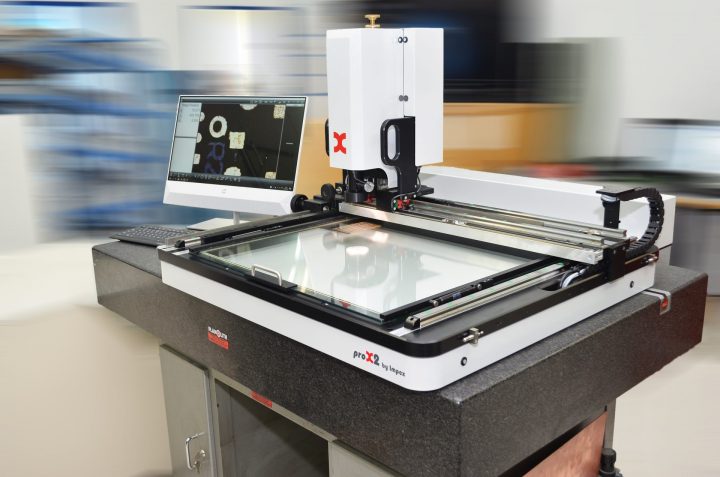

Metrology Measuring Machine With CCD Camera And Manual Axes System

MEASURING WAS NEVER SO EASY ...

Do you know the problem that your measuring application can be operated just by well-trained engineers?

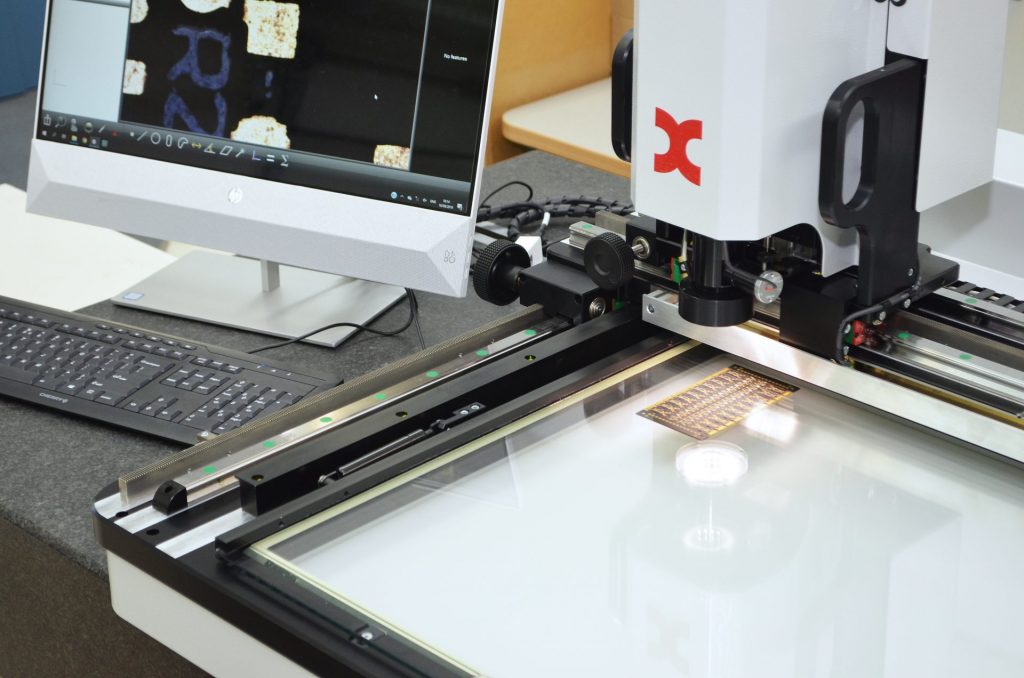

Impex Leiterplatten GmbH developed now its newest measuring machine called proX2. The focus during development was the easy handling. This system is the perfect cost effective start into high-tech measuring. The return-of-invest point is easily reached.

Manual Measuring Machine with Big Measuring Area

The X, Y and Z axes will be moved by hand to the measuring position. Hand wheels realize the fine positioning. The axes have to be placed by hand but the program procedure can be saved in a program. Then the software will control the light, add the tolerances and target values and a red arrow will guide the operator to the next measuring position. The software will measure automatically when the elements are in the camera field of view. Also the export to a defined file happens automatically. This makes series measurements possible.

The size of the measuring area is 640x540x20mm. The machine is equipped with white through light, white diffusive ring light and coaxial top light.

Operation via Touch Screen and Automatic Element Recognition

The measurement is really very simple. This is the procedure: The user places the object into the field of view of the camera and touches every needed element. The software will recognize the contour and geometry of the element. The results and the part view of all measurements will appear immediately.

For sure the operator can learn complex alignments and so different coordinate systems and zero positions. Only right alignments make sure that the measured result is right.

Every person can immediately start the operation without long training due to it is so easy. Simply touch it on the screen.

Professional Edge Recognition

Not all objects can be separated with a good contrast. In other machines it is very complicate to measure elements with a bad visible edge contrast. It is complicate or not possible. Only well trained operators can do this. In the new proX2 this is very easy. Touch the bad edge and the software will learn where the edge is.

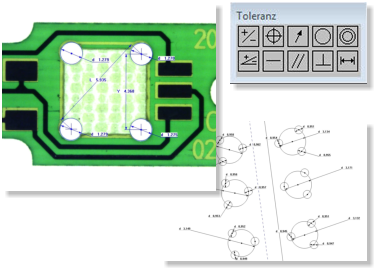

Additional Constructions, ISO Tolerance Check and Results in the Part View or Camera Image

The machine is also able to create additional constructions between already measured elements. There will be new projections, new zero points or alignments and new distances or intersection points. The operator can define ISO tolerances for all needed results. This realizes a fast good/bad check.

New and really great is the possibility to add results, names or other information into the part view or camera image. This is very helpful for all measurement in the field of view of the camera or for your labeled part view in your report. Also here is just a finger touch necessary. This feature gives a wonderful overview of your measurements. Other machines export the results but without any relation to the measured panel. The labeled part view with all bubbles can be automatically used in the report software “Statistics”.

Statistics Software

Professional Reports and Statistical Evaluation

We designed the report software „Statistics by Impex“ to create professional reports of Impex measure machine results. The different result formats will be recognized automatically. After the import the operator is able to swap between the different report types.

Following Report Types are Possible at the Moment

- Drill Statistic Report

- Area A,B,C,D (4-quadrant) drill analysis

- Area AB, CD & AC,BD drill analysis

- Real Position Report

- First Article Report

- Process Accuracy Analysis

- VDA Report (First Article Report in ISO list format)

- Quick Scanner Report

- 3D hole or bump analysis