The small measuring station quickcheckZ8000 determines material thickness or material depth up to 8mm and shows the measured value on a digital display.

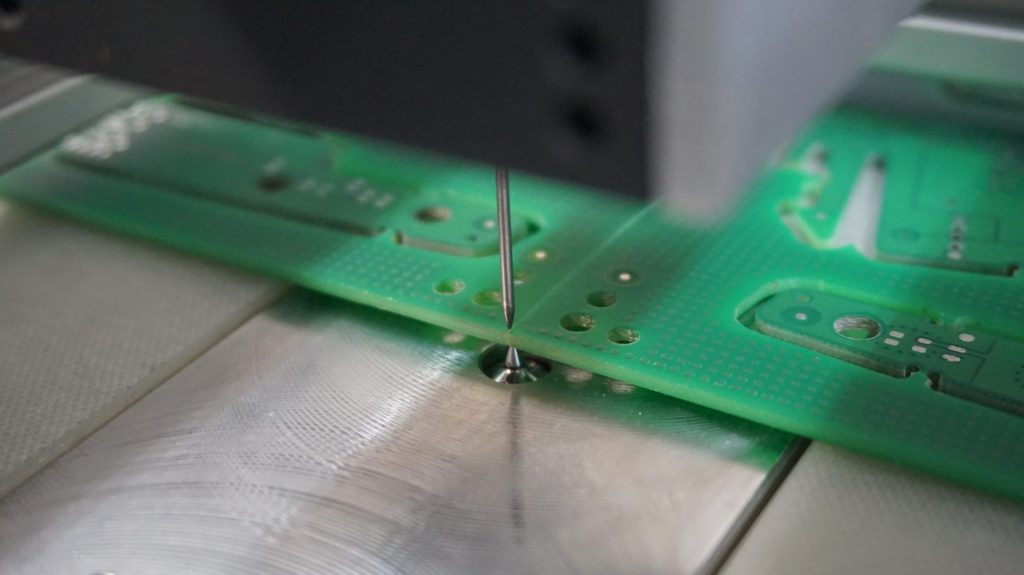

Measuring procedure of the thickness measurement

The measuring object and the measuring point are positioned manually. A laser point indicates the measuring position. After pressing a foot switch, a reference pin is moved from a recessed lower position into the measurement object. When the reference pin is fully extended, the top is 2mm above the contact surface.

After a freely definable time, the probe is positioned on the reference pin from above. The measuring object leads to an early stop of the probe and thus to the display of the material thickness.

Measurement procedure of the depth measurement

Here, the reference pin movement is deactivated using a switch and a recessed steel base plate is inserted. The measuring object and thus the measuring point are positioned manually. A laser cross shows the measuring position again. Now the probe can be referenced to a desired height. Each subsequent measurement at a different point gives a depth of difference.