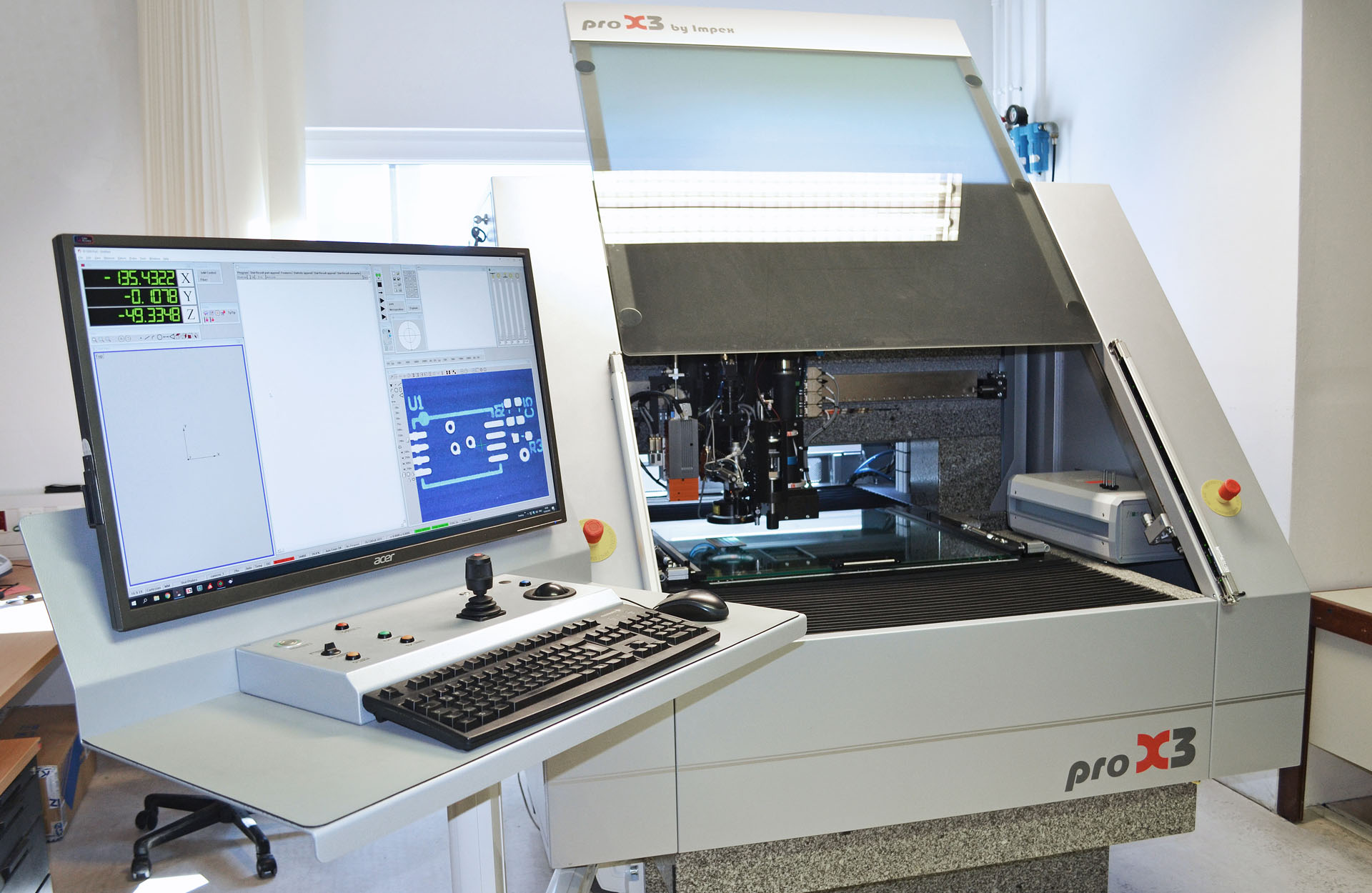

IMPEX Measuring Service

For sure, also our quality department is equipped with the newest Impex measuring solutions. Our measuring service is used to check the quality of our production and additionally we offer measuring service for customers.

Drill check with scanner

- Number of holes per panel: up to 1.3 Mio.

- Diameter: ab 80µm

- Statistic reports

Statisitic

- Graphical scatter diagrams

- Min. and Max. values

- Sigma (standard deviation)

- Mean deviation

- Cpk, Cp

- Good / Bad analysis with green / red DXF part view

- List of all missing holes

- List of all over counting holes

- Area check (dust and hole quality check)

- Diameter check including statistical overview

- Group avaluation (specific areas on the PCB, e. g. for twin machines)

First Article Reports or Series Reports with Scanner

- 100% check of all elements (holes, lines, arcs)

- Additional dimensioning (distances, angles, intersection points and many more)

- Sorting good / bad

High precision measuring with CCD Metrology system

- Measuring of very complex elements

- Highest precision level

- Depth measuring with CCD camera of laser sensor

3D topography scanning with Korad3D sensor

- Topography with <1µm depth accuracy

- Analysis of profiles, roughness, scratches and many more