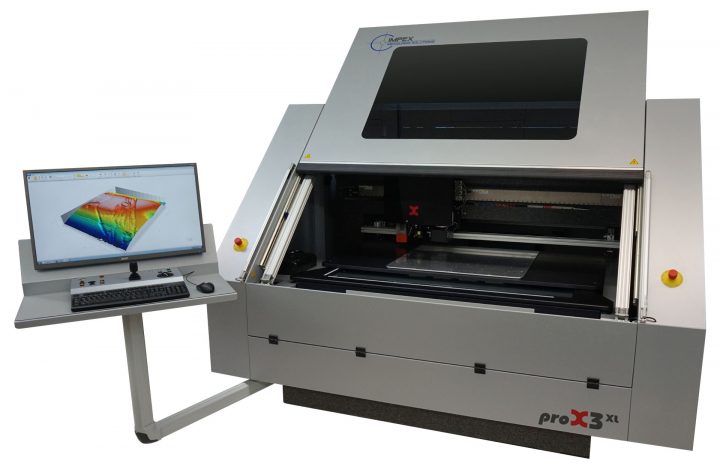

Modular measuring machine with different measuring options

Large measuring range! The proX3 XL has a measuring area of 1270 x 810mm.

The integrated and fully automatic vacuum table can be loaded quickly and easily. This opens up new possibilities for evaluating objects, since all integrated systems can be used on the glass and on the vacuum table.

Equip the Machine with different Measuring Options

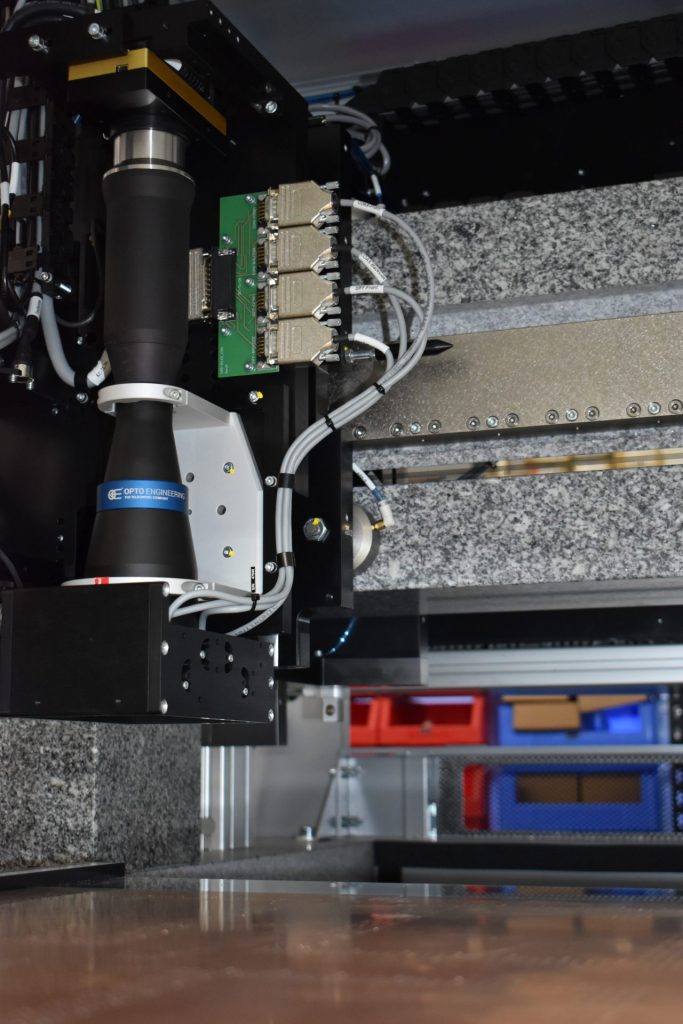

CCD Metrology

The metrology system is a powerful tool to measure nearly all applications in the PCB industry. A Matrix CCD camera with a 12x zoom objective deliver the image from the objects.

Tactile 5-way sensor

Different lengths and contact balls can be selected from a large variety of probe tips. The probe tip can be replaced quickly and easily using a magnetic coupling. The metrology system executes the fully automatic positioning to the object and determines its position by gently touching it.

High Speed Scanning

The high speed scanner system was developed to measure a high number of elements in a very short time especially for the PCB industry. The system is able to measure more than 1 million holes.

Non-Contact Laser Sensor

The principle of the measuring process is laser triangulation. A laser beam measures the depth of the surface. These depth point clouds generate best fit lines or patches. The sensor can be used to measure for example the depth of routed areas, height of pads or similar elements.

3D Topography Measuring

KORAD3D is a compact measuring unit which works on the principal of white light Interferometry. The result is a 3D image of the measured object with a precision of 0.04mil on optical rough surfaces.

Optical fiber measurement

With the 125 µm optical fiber, completely new possibilities for drill hole analysis are available. In this way, copper layers in multilayer can be determined non-destructively, roughness and drilling quality of a hole can be assessed, problem-free depth measurements can be carried out and many other applications.

IMPEX proX3

Precision Starts at the Base ...

Maintenance free system due to non contact drives The backbone of the machine is a high precision Impalla granite which was designed in a solid bridge construction. All positioning- and guiding systems are realized with air bearing solutions. Thus the axes have absolutely no contact with the granite. The drives are U-type linear motors. Just the cleaning of the machine is necessary. The scales have a resolution of 0.008mil and the temperature influence is almost nothing.

Ergonomic operation is very important for us. The operator works on a big operation panel which consists of a standard keyboard, mouse and 24" flatscreen monitor.

The Metrology SystemIK5000

The metrology system is a powerful tool to measure nearly all application in the PCB industry. A Matrix CCD camera with a 12x zoom objective deliver the image from the objects. The measurement is based on edge detection. Functions like circle, arc, line, centre of gravity and lot more measurements can be done. The system measures on 2½ axes (XY and Z height).

Measurements can be made manually or inside of a recorded program fully atomized. The programming is very simple and easy to learn. The construction features like distance, point, arc are helpful tools to generate all application data which are needed . Many tolerance settings can be applied to the features. Even the taken objects can be calculated in different way’s like best fit, min superscribed, max inscribed calculation and more.

Programs for the automatic run can be generated manually or with the help of a DXF file of the target element. An optional NC-DXF converter is able to create DXF files in the right format from NC programs like Excellon, Posalux or Sieb & Meyer.

Depth measurements with a high precision can be done via auto focus on an object. Thus the distance calculation of different depth measurements makes it possible to measure the thickness or depth of varnish, depth controlled holes and depth controlled milled patches or scoring lines.

The biggest benefit of the CCD Metrology System is the dynamical light- and video edge detection adjustment during the measuring process. Thus the system is able to measure very complicate edges and objects.

The High Speed Scanning System

The high speed scanning system was developed to measure a huge number of drilled holes in a very short time with a very high precision. It was especially designed for the PCB industry but includes also special features for other business areas. The scanning process of the whole area needs about 1 minute. An incredible measuring algorithm calculates thousands of elemends in some seconds. An optional top light system is also available. This can be used for blind via inspection or drill deflection evaluation. The top light is programmable and designed with fibre optics technique.

An array of statistic information is available, which includes but is not limited to Cpk, sigma, and average value. A deviation diagram immediately displays the quality of the measured products. In the case of an error analysis, the objects do not need to be rescanned since all digitized pictures are stored on the system. A measuring machine with the high speed scanner and the CCD metrolgy system makes it possible to combine the scanner result with the CCD camera. An element out of tolerance in the scan report can be checked again in more detail with the CCD camera. This feature saves time and generates a high inspection rate. The measuring machine is the perfect tool for 100% accurate product control.

The new Scan-Contour measuring function is a quick measuring tool for 2-D objects. Lines, circles and arcs are probed with the “Best Fit” method and a speed greater than 700 features per second. The constructions of distances, points and angles are also possible. The input format is a DXF data set, which provides the optional NC-DXF converter and converts Excellon or S&M drill- and routing programs.

If all necessary elements refer to the nominal, an additional programming is not necessary. A freely programmable tolerance database can be set up. The free Step & Repeat function is an outstanding tool to measure the multiplicity of the same part without additional programming.

The operation is just as simple as the drill scanning. An internal wizard leads the operator through the menus and in a few minutes the measuring is complete.

Statistics Software

Professionelle Berichte und statistische Aufbereitung

Die Report Software „Statistics by Impex“ wurde entwickelt, um aus den verschiedenen Exportformaten der Impex Messmaschinenlösungen professionelle Berichte zu erstellen. Dabei werden die Daten automatisch erkannt und ausgewertet. Nach erfolgreichem Import kann zwischen mehreren Berichttypen gewechselt werden.

Folgende Berichtarten sind derzeit in der Report Software „Statistics“ verfügbar

- Bohren Gesamtstatistik

- Bereich A,B,C,D (4-Quadranten Analyse)

- Gruppenreport AB, CD & AC,BD

- Echtpositionsanalyse

- Erstmusterprüfbericht

- Prozess Genauigkeitsanalyse

- VDA Erstmusterprüfbericht

- Quick Scanner Report

- 3D Loch - bzw. Bump - Analyse

Statistics Software

Professional Reports and Statistical Evaluation

We designed the report software „Statistics by Impex“ to create professional reports of Impex measure machine results. The different result formats will be recognized automatically. After the import the operator is able to swap between the different report types.

Following Report Types are Possible at the Moment

- Drill Statistic Report

- Area A,B,C,D (4-quadrant) drill analysis

- Area AB, CD & AC,BD drill analysis

- Real Position Report

- First Article Report

- Process Accuracy Analysis

- VDA Report (First Article Report in ISO list format)

- Quick Scanner Report

- 3D hole or bump analysis